SINOBATOO is launching a new printing craft on surface of mini kegs and growlers; it is called Water Transfer Printing, what’s this? And how does it work?

Water Transfer Printing also known as Hydro-Graphics, immersion printing, hydro dipping, water-marbling or cubic printing, it is a common method of applying printed designs to three-dimensional surfaces. Today, SinoBatoo is using this hydrographic process on stainless steel 304, offer more choices to our customers for carrying a colorful and unique mini keg and beer growler.

What’s the process of Water Transfer Printing on mini kegs?

- Making film

First of all, you should select images or patterns from existing database (Animals, Stone, Mountain…) or you can also create your own design. These images would use for making water-soluble polyvinyl alcohol (PVA) film.

Film cost depend on how many colors including on your selected image, normally film workshop would charge nearly US$100 per color. Please notice, film cost is not the only cost we would charge, there would be set up on pattern and printing labor cost as well.

- Spray Base Coat

A base color coat is necessary and pre-treatment process before Water Transfer Printing; it is applied to surface of our mini keg and beer growler. The application of base coat is not only protecting the surface of stainless steel, but also enriches the color of the finished product.

To achieve better effect, we would suggest some common color matching between base coats and patterns, such as wood grain suppose to use brown or khaki base coat. And if your design is stone grain, white base coat would be better.

Each pattern will appear radically different depending on the underlying base coat applied. Our mini keg often looks great with a silver or white coat.

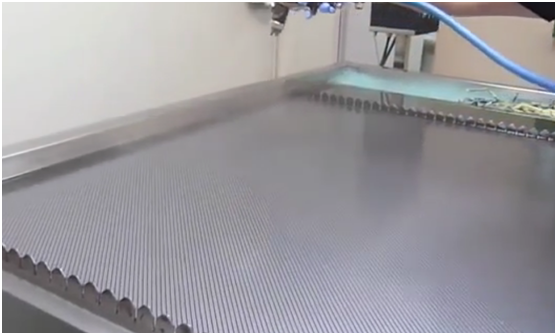

- Place film on water surface

Hydrographic film should be carefully placed on the water’s surface in the dipping tank. The film is water soluble, and dissolves, leaving only the pattern floating on the water. Surface tension will allow the pattern to curve around any surface.

- Spray Activator

After 30s-50s’ floating, a special activator need to be sprayed on Film, which dissolves the components in the pattern’s colors without affecting its structure and appearance.

- Dipping

The Mini keg is immersed in the water through the floating layer of liquefied pattern. The pressure of the water will cause the pattern to smooth itself evenly around Mini keg in all places and adhere to it. Finally, the part completely covered in the pattern.

NOTED: It request to using uniform speed when putting mini kegs into water, once the complete part went into water, please churn water, in case the residue film adhere again, then take out of mini keg quickly. The adhesion is a result of the chemical components of the activator softening the base coat layer and allowing the ink to form a bond with it. High quality activator is one of the most important factors in producing a high quality, professional Hydrographic transfer.

- Rinsing and Drying

Mini kegs are washed to remove film and color residues, and then needed to be dried in short time. During this process, it would request to operate under below conditions: Water pressure is not too big, and temperature is not too high, otherwise pattern would be destroyed.

- Clear Coating

After a close quality control inspection, mini keg can be clear coated to protect the surface and to provide a shiny appearance.

Why SinoBatoo start using Water Transfer Printing to decorate mini kegs, Swedy summarized the advantages Water Transfer Printing over traditional printing like silk, etching and laser engraving.

First, multicolor pattern, you can put any colorful pattern you desire, no limits for color.

Second, pattern can be printed to three-dimensional surfaces, not only flat side, but many irregular surfaces, nearly the whole part of mini keg and beer growlers, even on the bottom of mini keg.

Third, environmental, the residue and liquid water won’t pollute environment.

Do you have a good understanding for Water Transfer Printing now? Hope so.

PS: Even though the cost of film and labor are higher than other printing method, still many customers are interesting with Water Transfer Printing to apply on mini kegs. Contact us if you have any query.